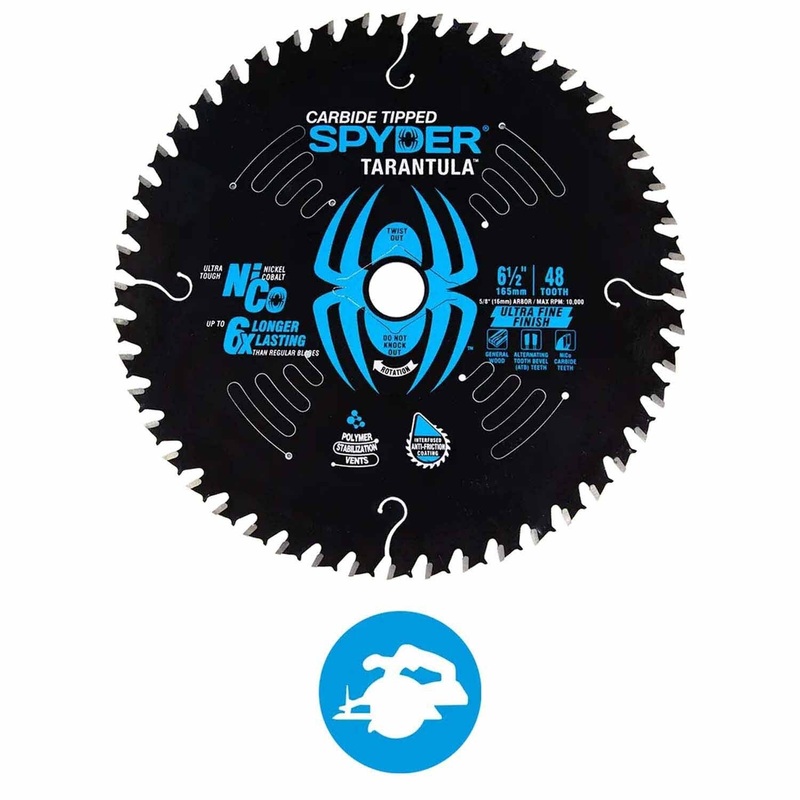

Spyder 13500 6-1/2-Inch 48-Tooth TCT Steel Cutting Circular Saw Blade

$35.37

$44.21

Spyder 13500 DescriptionSpyder Tarantula metal-cutting circular saw blades are the ideal choice for clean cutting steel and other metal profiles. These high-performance blades last up to 35x longer than standard bonded abrasive cutting wheels and make thos

Spyder 13500 Description

Spyder Tarantula metal-cutting circular saw blades are the ideal choice for clean cutting steel and other metal profiles. These high-performance blades last up to 35x longer than standard bonded abrasive cutting wheels and make those cuts up to 10x faster. Ultra tough NiCo2 carbide cutting teeth, made with upgraded nickel cobalt, feature a modified triple chip grind for unsurpassed cutting speed, life, and cleanliness.

Spyder 13500 Includes

- (1) Circular Saw Blade

Spyder 13500 Features

- Up to 35x more cuts than bonded abrasive cutting wheels

- Up to 10x faster than bonded abrasive cutting wheels

- Upgraded ultra tough NiCo2 carbide cutting teeth make the cleanest cuts in steel and other metals

- Dramatically cooler cutting and burr-free cuts with less sparks than those made with a bonded abrasive cutting wheel

- Interfused anti-friction coating prevents blade binding and protects against heat and corrosion

- Polymer-filled stabilization vents reduce noise and vibrations for a cleaner, straighter cut

- Designed for use on metal-cutting circular saws that feature high-torque, low-RPM motors

Spyder 13500 Specifications

Related products

N126140 DeWalt Miter Saw Handle Clamshell Set

$9.90

$12.38

330034-02 DEWALT Black & Decker Chuck Key

$3.99

$4.99

Reviews

There are no reviews yet.